Over

+

Years of Experience

More Than

+

Customers

More Than

+

Instruments Installation

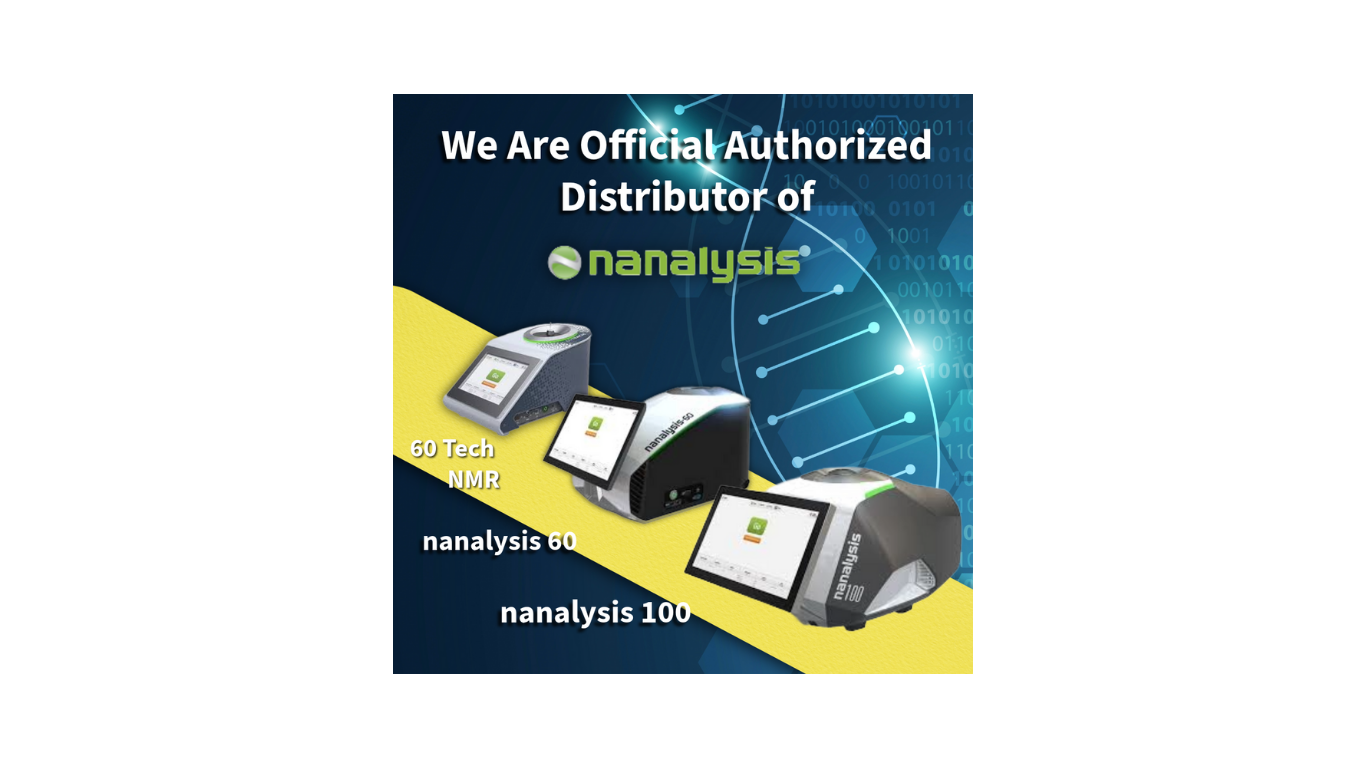

We exclusively represent and support leading brands of analytical & scientific instruments including:

Our Customers Industries

We serve customers in the following sectors :

University & College

Food & Agriculture

Research & Instituitions

Palm oil

Rubber / Latex

Oil & Gas

Commercial Testing Laboratories

Electronic/Electric

Pharmaceutical Manufacturers

Specialty Chemicals / Dispersion

Polymer

Semiconductors

Natural products

Automotive

And Much More

Our Products

Our Suppliers

Subscribe to our newsletter

Stay in touch with us to get latest news and promotions