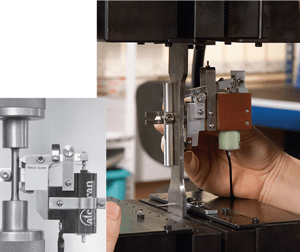

Epsilon ONE Non-Contact Video Extensometer

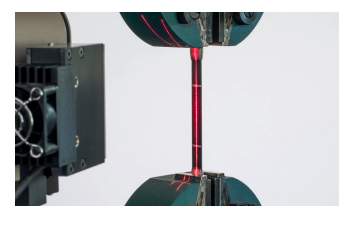

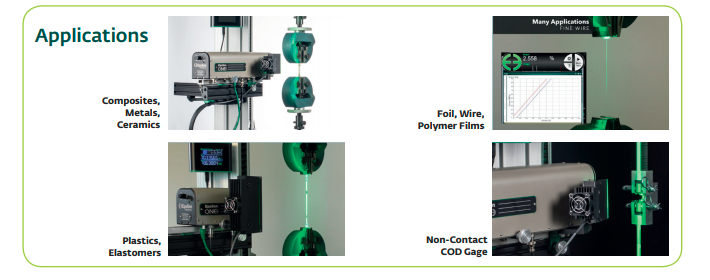

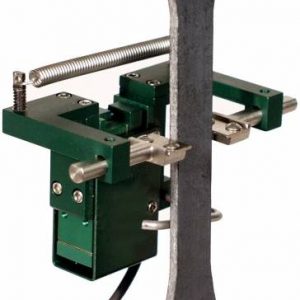

Epsilon ONE optical non-contact extensometers perform high-accuracy, high-resolution, non-contacting axial strain and displacement measurement. These extensometers are suitable for testing high-modulus materials such as metals and composites, high-elongation materials, thin or delicate specimens, cyclic fatigue, strain-controlled testing, deflectometer applications, and measuring crack opening displacements. Strain or extension is measured and output in real time.

Epsilon ONE’s high resolution and ISO 0,5 / ASTM B-1 accuracy classes make it suitable for non-contact measurement of a wide range of strain values, from very small strains required to measure modulus of metals, composites, ceramics and CMCs through elastomers and everything in between.

Key Features:

- Always on, always ready: Unlike DIC systems, software interactions are unnecessary when running repetitive tests.

- Always real-time: Post-processing is never required, even at the highest data rates.

- Faster throughput with Instant Reset: Auto-start repetitive tests without touching the extensometer or software.

- Reliable, automatic mark detection: Robust tracking of bright or dark marks beyond 1000% strain and speeds >1500 mm/second.

- Laser assist alignment system: Provides an instant visual spot-check for specimen alignment and optics positioning.

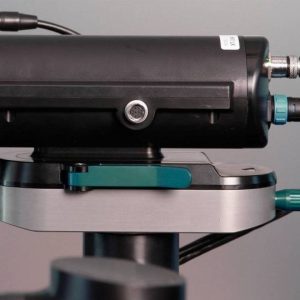

- Precision Telecentric Design: Epsilon ONE’s telecentric lenses prevent common sources of error.

- Fully factory calibrated: Epsilon calibrates using the industry’s most comprehensive process to correct for scaling, skew, lens distortion, and uneven lighting. A2LA accredited factory calibration, traceable to the SI; no grids or bars are required for calibration.

- Optional Touch Interface: Access and control the Epsilon ONE without a computer.

- Retractable high-stiffness mounting: Industry-leading ease-of-use while maintaining maximum dynamic range and vibration rejection.

- Selectable multi-line specimen marking: Automatically identify and report the region of highest strain concentration, in real time.

- Faster Testing: Save time with industry leading 200+ Hz dynamic range and automatic gain compensation filters.