Why FT-NIR Spectroscopy?

FT-NIR spectroscopy offers a practical alternative to time-consuming, solvent-intensive, wet-testing methods and liquid chromatography techniques. Its ability to test materials quickly in their production state allows routine analyses to be carried out at the line, rather than in the lab.

Some of the advantages are:

- Accuracy, precision, short time of analysis

- Limited sample preparation

- Replaces typical time consuming, expensive, and hazardous primary analysis

- Spectral data in the NIR region can be acquired by diffuse reflection, transflectance, or transmission of the light on the sample

- Analyze a wide range of samples such as gels, powders, pellets, pastes, slurries, coarse solids, opaque and clear liquids &, etc

- Accessories and modules swap out in seconds, giving you the ultimate sampling flexibility. Whether you're analyzing food, beverages, polymers, or pharmaceuticals

What is FT-NIR?

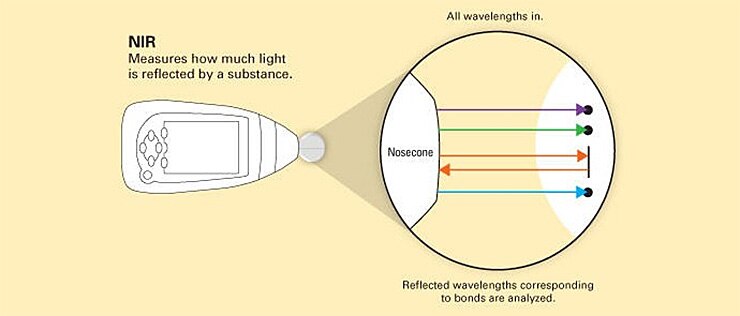

In NIR spectroscopy, the unknown substance is illuminated with a broad-spectrum (many wavelengths or frequencies) of near-infrared light, which can be absorbed, transmitted, reflected or scattered by the sample of interest. The illumination is typically in the wavelength range of 0.8 to 2.5 microns (800 to 2500nm). The light intensity as a function of wavelength is measured before and after interacting with the sample, and the diffuse reflectance, a combination of absorbance and scattering, caused by the sample is calculated.

Light is absorbed in varying amounts by the sample at particular frequencies corresponding to the combinations and overtones of vibrational frequencies of some bonds of the molecules in the sample. Specifically, the bond vibrations between oxygen and hydrogen (OH), carbon and hydrogen (CH), and nitrogen and hydrogen (NH) result in NIR absorbance bands.

The bands seen in the NIR are typically very broad, leading to spectra that are more complex to interpret than FTIR spectra; it can be difficult to assign specific features to specific chemical components. Careful development of a set of calibration samples and application of multivariate calibration techniques is essential for near-infrared analytical methods.

What is reflection analysis by NIR?

Samples in cups, bags, vials, or set directly on the integrating sphere are interrogated by NIR light energy and the light is transmitted, directly reflected, absorbed, and diffusely reflected.

The diffusely reflected light is collected and sent to a detector. By collecting the amount of light that is diffusely reflected from solid samples you can predict component concentrations or identify samples.

What is transmission analysis by NIR?

Samples in tubes, vials, or cuvettes are held in a module and interrogated by NIR light energy. The source light can be transmitted, directly reflected, scattered, absorbed, and diffusely reflected from the samples.

The light that transmits through the sample is collected by a detector. By collecting the amount of light that is transmitted thru a sample you can predict component concentrations or identify samples.

How many samples are required to develop and validate a calibration?

It depends on how challenging the application is, how many components will be in the calibration and if the most ideal standards are used for calibration development.

Transmission analysis on liquids often requires fewer standards than reflection analysis, especially on in-homogeneous solids.

More components require more standards in the calibration model than a single component model. Standards used in NIR calibration models must take into account all the chemical, physical, and sampling variations that the calibration will be exposed to when implemented for QC testing.

For some applications, an ideal standard set can be synthetically generated in the lab but when pulling samples off the production process running within specification, it generally takes significantly more standards to model in all the needed variations.

At a minimum, 10 times the number of components in the calibration model will generate a starter calibration to prove the feasibility of the calibration.

What are the advantages of FT-NIR versus a dispersive NIR?

FT-NIR spectroscopy provides several clear advantages over classical dispersive techniques. These advantages are most important when analyzing the NIR spectra of chemicals, polymers, and pharmaceuticals.

FT-NIR spectrometers are mechanically simpler than traditional dispersive instruments because the moving mirror in the interferometer is the only continuously moving part in the instrument. Thus, there is very little possibility of mechanical breakdown.

In most dispersive instruments, gratings and filters must move in order to generate a spectrum. The benefit of mechanical simplicity is a more reliable, robust scanning mechanism that translates into a more reliable analyzer.

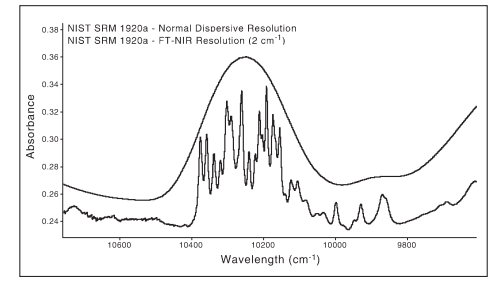

Dispersive NIR instruments rely on a prism or grating to separate (resolve) the near-infrared frequencies. The best grating can at best separate frequencies 50 cm-1 apart. However, most pharmaceutical, chemical, and polymer samples have spectral information that resolves at 8 cm-1. Important spectral information for these types of samples cannot be measured on dispersive instruments so they employ a slitting mechanism to achieve higher resolution. Because the slit limits the amount of beam that is measured, a substantial energy loss is incurred, making it difficult or impractical to measure samples at higher resolutions. Because the stroke length of the moving mirror determines resolution on an FT-NIR system, there is no degradation of optical throughput as is caused by the slits in dispersive instruments.

With no degradation in performance, high-resolution spectra can be quickly and easily measured by an FT-NIR system. This advantage is clearly shown in the spectrum of the NIST SRM 1920a standard reference material (Figure 1). With more spectral information, less reliance is needed on sophisticated chemometric algorithms, which translates into fewer standards being required to develop methods.

Figure 1: Comparison of NIST SRM 1920a spectra generated on an FT-NIR and dispersive instrument

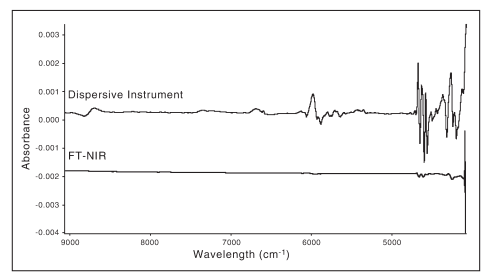

The use of an internal reference laser by FT-NIR instruments is referred to as Connes Advantage. The benefit of internal calibration is accuracy and precision of better than 0.1 cm-1. Shifts in peak positions from scan to scan create artifacts in the data (Figure 2).

Dispersive instruments utilize a mechanically complex prism or grating which causes errors in peak positions and inaccuracies from scan to scan. With the inherent inaccuracy problems of dispersive instruments, reference materials must be employed for calibration. The external calibration has to be repetitively performed, adding difficulty and operator error to measurements.

Figure 2: Subtraction of repeated scans of a polystyrene standard confirms that the presence of spectral artifacts is greater in dispersive instruments

With negligible FT-NIR instrumental artifacts due to wavelength inaccuracies, fewer standards are required, providing better results than with dispersive instrumentation. In addition, without wavelength error, large commercial digital libraries can be employed to quickly identify materials.

In conclusion, these advantages make FT-NIR measurements extremely accurate and reproducible. Thus, it is a very reliable technique for the positive identification and quantitation of any sample. This makes FT-NIR an invaluable tool for quality control and quality assurance applications.

How is NIR Spectroscopy Used in the Food, Beverage, and Feed Industries?

Companies in the food and feed industries are under increasing pressure to produce products that meet customer specifications while increasing plant production and profitability.

Near-Infrared spectroscopy is a solution that helps companies optimize their production process and guarantee products are meeting specifications. The Thermo Scientific Antaris Analyzer with INGOT™ calibration packages offers a pre-calibrated solution using FT-NIR. Traditionally, quality tests have been undertaken by lengthy chemical methods, which are labor-intensive, time-consuming, and require experienced technicians.

Learn more about the benefits of near-infrared for flour, feed, and ingredient testing to:

- Monitor and control your process to maximize production and profitability.

- Rapid, multi-component analysis simultaneously without chemical or disposable costs.

- Near-infrared can save you time, money, and analytical resources.

- Ensure product meets final product specifications.

- Determine the quality of incoming ingredients at intake

4 reasons to switch to Thermo Scientific FT-NIR Analyzer:

For more information about FT-NIR Analyzer, see here.