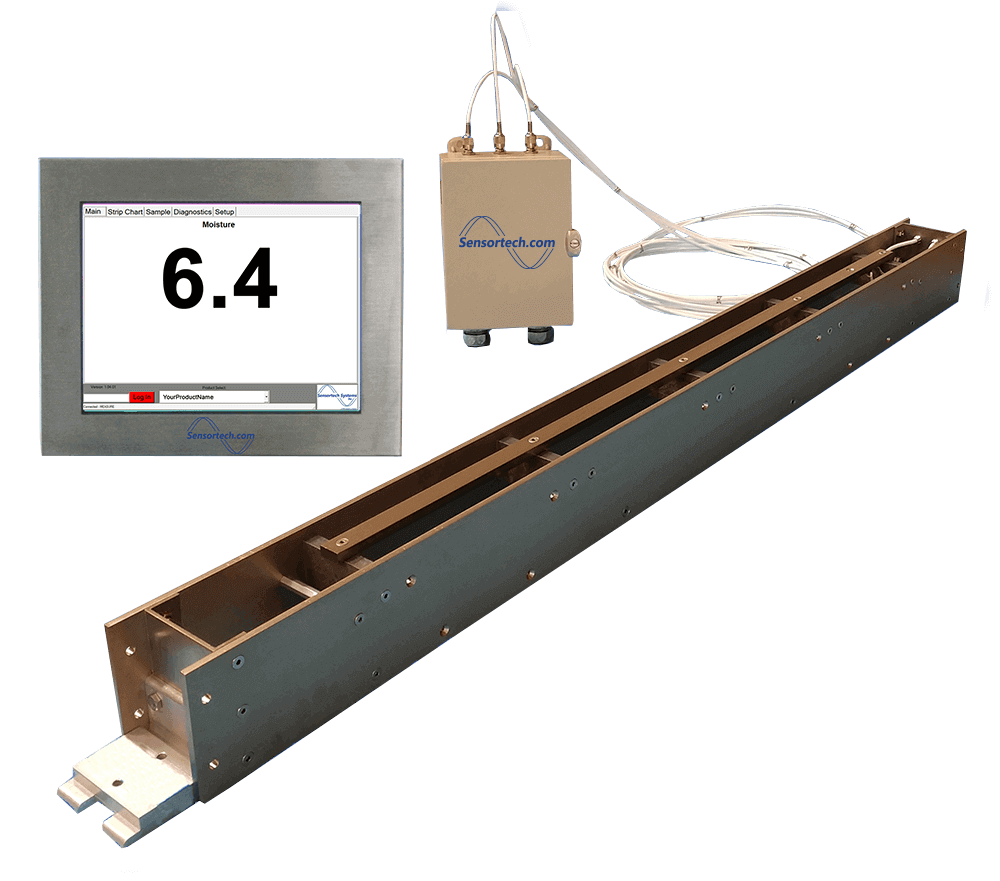

ST-3300 RF Moisture Sensor – Advanced Process Moisture Control

High-Precision RF Moisture Measurement for Industrial Process Optimization

The ST-3300 RF Moisture Sensor by KPM Analytics is a state-of-the-art process moisture analyzer designed for real-time, inline moisture measurement in chemical, mining, textile, agriculture, and building material industries. Utilizing radio frequency dielectric (RF) measurement technology, the ST-3300 provides deep moisture penetration for accurate, full-line moisture control, helping manufacturers reduce waste, optimize drying efficiency, and enhance product quality.

With customizable antenna lengths, a rugged open-frame design, and high-temperature operation capabilities, the ST-3300 is the ultimate solution for critical moisture monitoring in kilns, dryers, conveyors, and material processing system.

Key Features:

✓ Advanced RF Moisture Measurement Technology

- Uses radio frequency dielectric principles for non-contact, deep moisture penetration.

- Provides high-resolution readings with accuracy levels as precise as ±0.02% for gypsum board and ±0.10% for wood panel board.

✓ Wide Application Range with High-Temperature Capability

- Operates in low, high, and ultra-high temperature conditions (up to 540°C / 1000°F).

- Custom antenna lengths (15 cm – 244 cm / 6 in – 96 in) for different installation environments.

✓ Real-Time Process Integration & Automation

- Interfaces with PC, PLC, and optional 12” touchscreen display.

- Supports 4-20mA output, RS-485, digital input, product temperature input, and Ethernet TCP/IP communication.

✓ Intuitive Analysis Software & User-Friendly Interface

- Provides real-time data visualization and reporting.

- Allows operators to manage and adjust sensor settings via PC or an optional touchscreen display.

✓ Customizable Installation & Mounting Options

- Designed for installation on conveyors, kiln/dryer exits, or material feed points for continuous monitoring.

Application Across Industries:

- Wood & Lumber Processing – Moisture control for sawdust, veneer, plywood, biomass, and wood pallets.

- Building Materials – Monitoring moisture in gypsum board, bricks, and composite boards.

- Textile & Nonwoven Fabrics– Ensuring consistent moisture levels in broad-woven and non-woven fabrics.

- Paper & Packaging – Quality control for pulp, paperboard, and converted paper products.