Over-Line Vision Process Control (VPC) Solutions – Smart Monitoring for Bakery Production

Real-Time Vision Process Control for Consistent Quality and Optimized Baking Performance

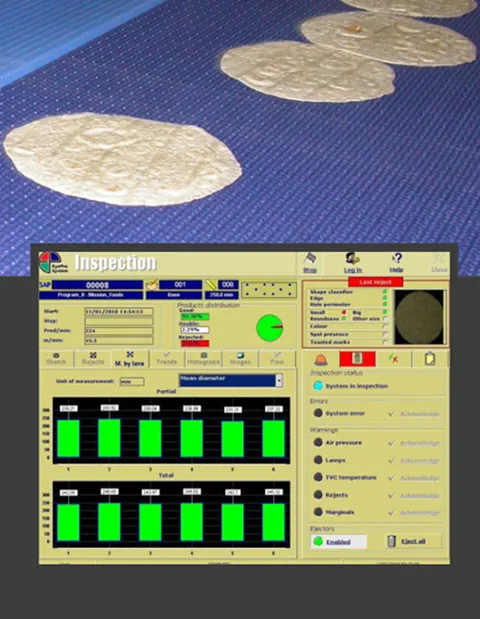

The Over-Line Vision Process Control (VPC) Solutions by KPM Analytics are designed to bring unmatched visibility and control to bakery production lines. Positioned directly above the conveyor, these non-contact vision systems continuously monitor products as they move through the production process – capturing real-time data on size, shape, color, and surface features.

Built for high-speed bakery environments, KPM’s VPC solutions help manufacturers ensure product consistency, reduce waste, and fine-tune oven and line performance through intelligent, image-based feedback.

Key Features:

✓ Non-Contact Over-Line Monitoring – Positioned above the line for seamless integration without disrupting flow.

✓ Real-Time Analysis of Critical Quality Parameters – Tracks length, width, height, color distribution, symmetry, and topping coverage.

✓ Automated Feedback to Oven and Line Settings – Enables immediate adjustments to optimize baking performance and product uniformity.

✓ Full Line Visibility – Monitors every product, ensuring 100% inspection and batch-to-batch consistency.

✓ User-Friendly Interface & Reporting – Provides operators with live dashboards, quality metrics, and historical data for process improvement.

Application Across Industries:

- Bakery and Snack Foods – Ensures uniform size, bake color, symmetry, and topping distribution.

- Frozen & Par-Baked Products – Inspects dough-based products before or after baking and assist in monitoring deformation or baking inconsistencies during transition phases.

- Confectionery & Sweet Snacks – Inspect the visual appearance of bars, filled pastries, or coated items, and ensures consistency in shape, surface finish, and coating application.