Basic Prinicple of Laser Diffraction

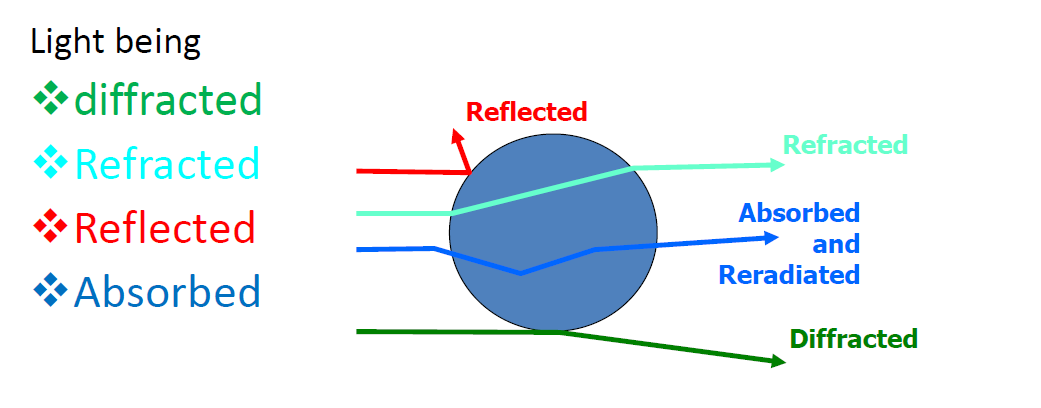

At the very heart of the laser diffraction technique is the relationship between light and surfaces (which can be freely interchanged with "particle" for our purposes).

When light strikes a surface it is either

- Diffracted

- Refracted

- Reflected

- Absorbed

Diffraction is also known as "edge diffraction" as that is where it occurs. Refraction occurs as light changes angle traveling throught the particle.

We can obtain information about the size of a particle using the angle and intensity of scattered light. Diffracted and refracted light is useful for this purpose; absorbed and reflected light works against this purpose and must be taken into account during measurement and size calculation.

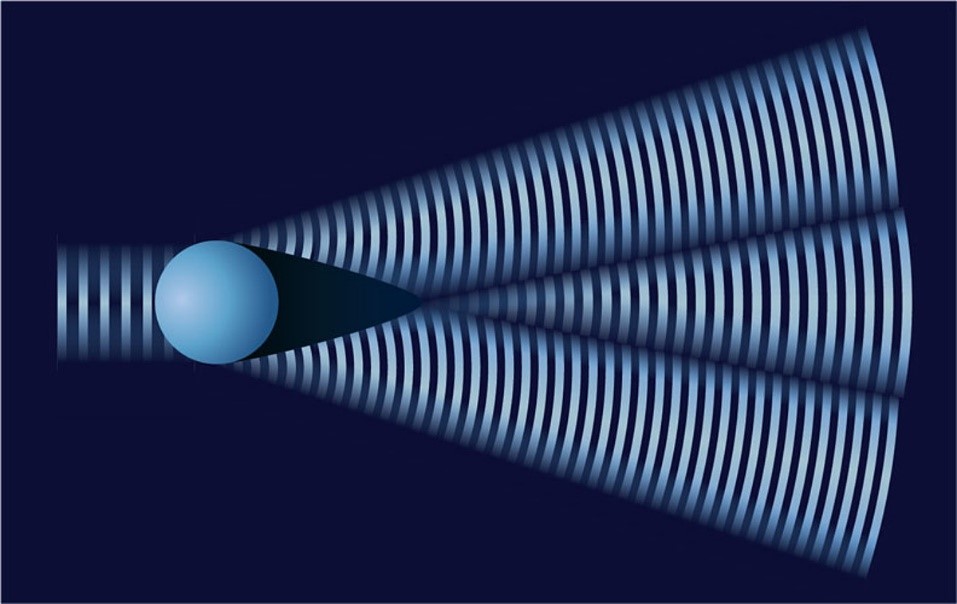

For particles larger than a certain size the vast majority of light is scattered by diffraction. The scattered light is at a relatively high intensity and low angle for these larger particles. The "certain size" is determined as a multiple of the wavelength of light used for the measurement and is typically approximated at 20 microns. Particles larger than this size communicate useful size information through diffraction and not refraction. This means the measurement will not benefit from the use of a refractive index to accurately interpret refracted light.

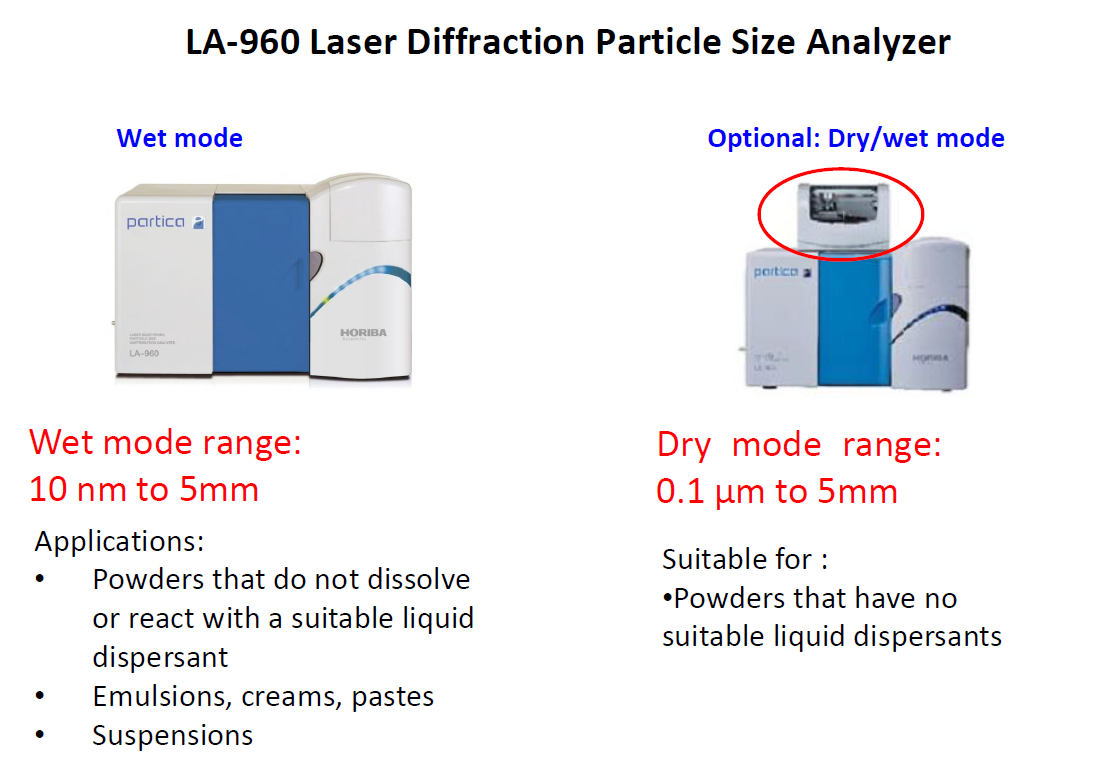

For particles smaller than 20 microns refracted light becomes increasingly important to calculate an accurate particle size. The scattered light is at relatively low intensity and wide-angle for these smaller particles. The use of a refractive index and the Mie scattering theory directly affects accuracy in this size range. Our LA-960 Laser Diffraction Particle Size Analyzer uses the Mie scattering solution by default and allow the user to input custom refractive index values

How does Laser Diffraction work?

Laser diffraction is about the relationship between particle size and the angle and intensity of scattered light. Light scatters more intensely and at smaller angles off of large particles than small particles.

Every analyzer, from the very first commercial prototype to the state-of-the-art LA-960 Laser Diffraction Particle Size Analyzer utilizes this principle. In fact, the analyzer itself does not measure particle size - it measures the angle and intensity of light scattered from the particles in your sample. That information is then passed to an algorithm designed to use Mie Scattering Theory which transforms the scattered light data into particle size information.

Both the hardware and software required to make a particle size measurement have gone through many revisions to improve accuracy, precision, reliability, and ease of use.

What is Laser Diffraction Particle Size Analyzer?

The basic workflow of a laser diffraction particle size analysis breaks down into two parts:

- Measure scattered light angle and intensity

- Transform that scattering data into a particle size distribution

Measurement quality is all about the analyzer itself: quality of components, engineering refinement, and a fundamental design which reflects basic principles. The core technologies are all mature, but as with many things, higher quality leads to superior performance.

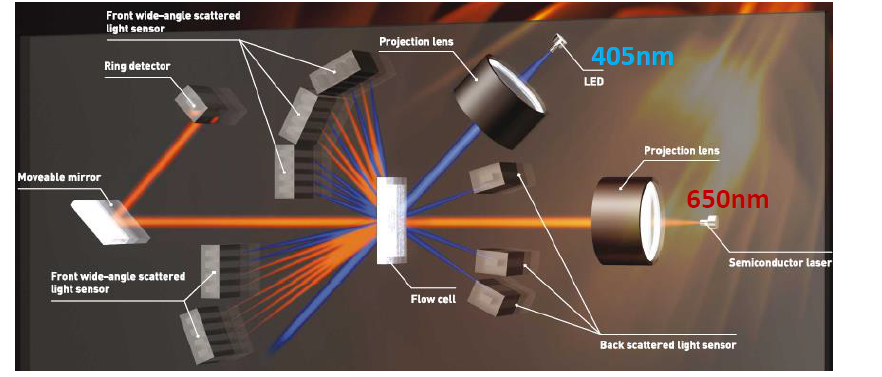

A typical laser diffraction optical system will include:

- Two light sources at different wavelengths

- 80+ photodetectors covering an approximate angular range of 0-170 degrees

- Very high-quality lenses, mirrors, and glass measurement cell

The LA-960 particle size analyzer represents the tenth generation laser diffraction instrument designed by HORIBA SCIENTIFIC. Hundreds of refinements to the basic design have been included to improve performance and usability. These refinements include:

- Maintenance-free, dust-free sealed optical bench

- Maximum stability and alignment with post-less, cast aluminum mountings

- Tilted measurement cell to reduce stray light noise

Ultra long-life solid-state light sources and detectors - Acquiring the best possible scattered light data is the basis of any reliable size measurement. The "raw" scattered light data is then passed to the calculation algorithm where it will be transformed into a particle size distribution.

Figure 1: A simplified layout of the LA-960 Laser Diffraction Particle Size Analyzer optical bench

Where do we apply Particle Size Analysis?

By using laser diffraction to measure particle size, this technique allows the analysis of particle behavior and consistency in a range of products. Understanding particle size gives manufacturers the information and control needed to ensure the delivery of high-quality products across a variety of industries.

Here are the 8 industries that have benefited from the application of particle size analysis.

- Agriculture - The particle size of agricultural materials directly affects release rate, potency, and working hazards. They can be naturally occurring, manufactured through natural processes, or chemical processes.

- Building Materials - Measuring and controlling the particle size distribution of building materials is important both in order to achieve the desired product performance and to control manufacturing costs.

- Ceramics and Electronics - Depending on the application, particle size can effect densification, transport, and mechanical properties. Particle size distribution has profound effects on the processing and function of these products.

- Food and Beverage - The size distribution of the particulates in many food products can affect the taste, appearance, stability, processability, and functionality of the final product.

- Pharmaceuticals and Biotechnology - Particle size analysis is an integral component of the effort to formulate and manufacture many pharmaceutical dosage forms. The size, distribution, and shape of the particles can affect bulk properties, product performance, processability, stability, and appearance of the end product.

- Polymers and Plastics - Measuring the particle size distribution of polymeric materials provides a high degree of control over a range of product performance characteristics.

- Specialty Chemicals - The particle size distribution of these materials determine the appearance, quality, functionality, and processability. These samples cover an extremely broad range of size distributions.

- Paper Products - Paper is manufactured from wood fiber slurries, fillers, sizing agents, and coatings. The particle size distribution of these materials directly affects properties such as gloss, brightness, opacity, color bleed, ink mileage, and more.

- And Much More

How To Select Laser Diffraction Particle Size Analyzer?

If you’re in an industry that relies on particle size analysis, you’ll benefit from investing in quality instruments to measure particle size. Therefore, select the most appropriate instrument for a given application depends on several variables.

The user must determine those factors that are most important for their application when considering the multitude of alternative particle sizing techniques and models.

Below is a list of considerations that should be addressed before a technique is chosen

- Current analysis technique or practice

- Size range

- Chemistry or Material

- Desired information

- Desired throughput

- Amount of sample available for analysis.

- Budget

Knowing the answers to the questions above will allow the analyst to rapidly identify appropriate particle analysis techniques.

With a wealth of experience in particle sizing, we are confident to help with method development for your products. For all your questions concerning Particle Technology, please contact our sales team to maximize the value of your instruments or book a free demo with us by filling up the form below.