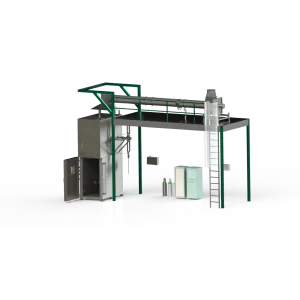

Cone Calorimeter (TCC 918)

Fire Testing System for Determining the Heat Release Rate, Dynamic Smoke Production and Mass-Loss Rate of Materials and Products According to the Oxygen Consumption Principle in Accordance with ISO 5660-1

The Cone Calorimeter is considered the most significant instrument in fire testing. It analyzes the heat release rate and the dynamic smoke production of a product and is based on the principle that the amount of heat released by the burning sample is directly related to the amount of oxygen consumed during forced combustion.

The amount of heat produced by a material is directly related to the severity of of a fire, expressed, for example, by its rate of spread. To test the flammability of a material, it is exposed to an external radiant heat coure during testing in the Cone Calorimeter.

The TCC monitors the development of fire from a very early stage. The ability to predict fire behavior on a real scale allows for the safe evacuation of buildings, airplanes, cars and boats in case of emergency.

The TCC 918 works in accordance with all established standards, including ISO 5660-1, ASTM E1354, ASTM E1474; ASTM E1740, ASTM F1550, etc

TCC 918 Tests – Data Source for Predicting Real-Time Fire Behavior

∙ Ignition Time (TOI)

∙ Time of combustion or extinction (TOF)

∙ Mass-loss rate

∙ Measurement of gas concentration for calculation of the amount of heat released

∙ Heat release rate (HRR)

∙ Combustion products (CO and CO2 quantities)

∙ Transmission and smoke gas density

∙ Total smoke release (TSR)

∙ Prediction of the real-scale fire behavior