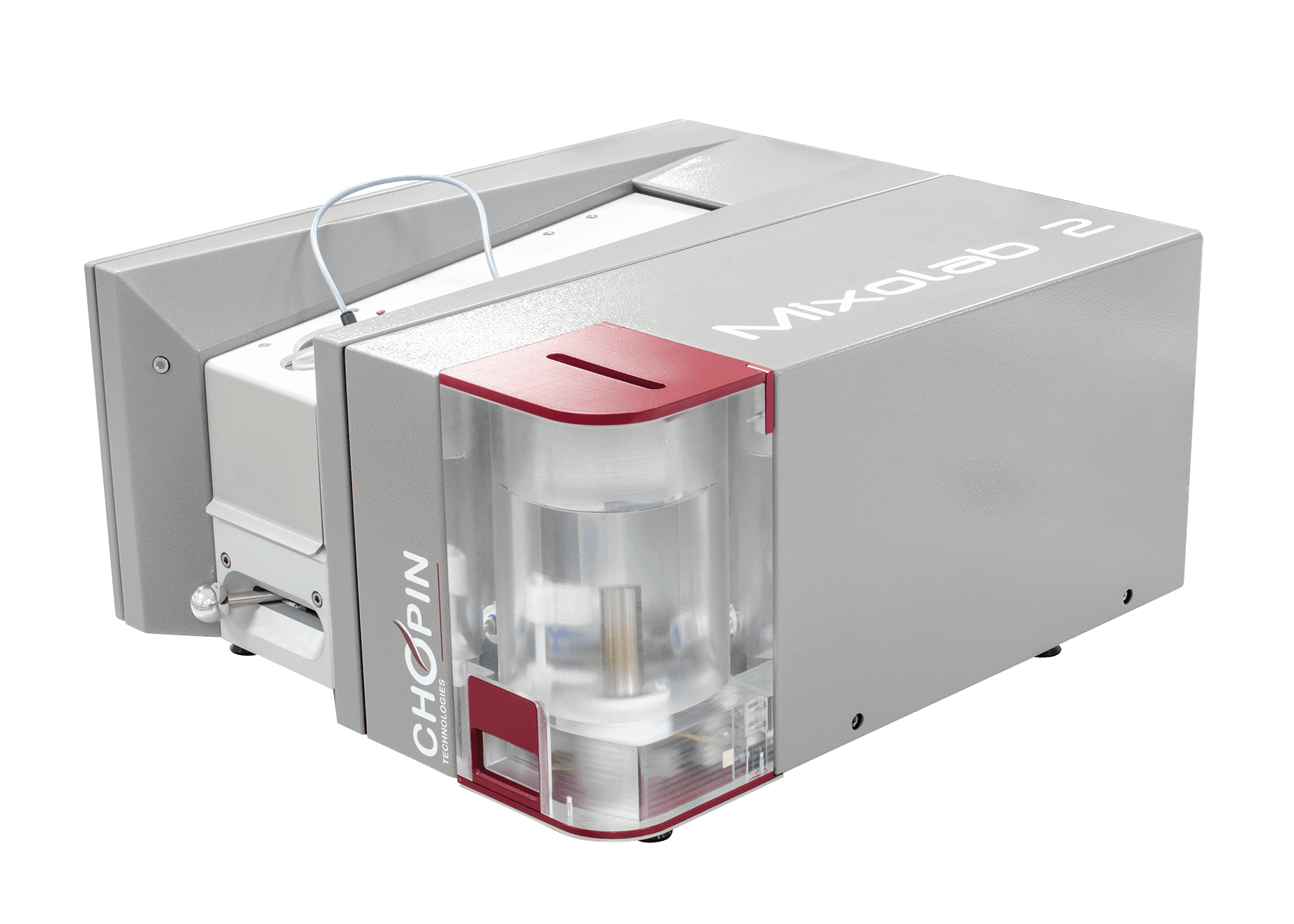

Mixolab® 2 Universal Dough Characterizer

Comprehensive Dough Analysis for Optimized Baking Performance and Quality Control

The Mixolab® 2 by KPM Analytics (CHOPIN Technologies) is an advanced dough characterizer that provides real-time insights into flour and dough behavior throughout the entire mixing, heating, and cooling cycle. Designed for millers, bakers, and food manufacturers, Mixolab® 2 evaluates water absorption, gluten quality, starch gelatinization, enzyme activity, and retrogradation, helping optimize production, enhance product consistency, and reduce waste.

Key Features :

- Full Dough Characterization in a Single Test – Measures key quality parameters including:

✓ Water Absorption : Determines flour’s hydration capacity.

✓ Mixing Stability : Assesses protein quality and dough strength.

✓ Gluten Resistance to Heat : Predicts baking volume and dough resillence.

✓ Starch Gelatinization & Viscosity : Evaluates crumb structure and texture.

✓ Amylase Activity : Controls enzyme effects on product color and volume.

✓ Starch Retrogradation : Predicts shelf-life stability and freshness retention.

- Real-Time Process Simulation – Replicates kneading, heating, and cooling phases to model actual baking conditions.

- Built-in & Customizable Protocols – Includes standard test methods and allows custom settings for unique flour compositions and baking requirements.

- User-Friendly Software

✓ Mixolab Profiler : Classifies flours based on six key quality criteria.

✓ Blending Law Tool : Predicts the outcome of flour blends for product formulation.

✓ Automated Control Charts : Tracks process variations for better consistency.

- International Standards Compliance– Meets ISO 17718:2013, AACC 54-60-01, ICC 173-1, GOST R 54498-2011, and GOST R ISO 17718-2015 testing requirements.

Industry Applications :

The Mixolab® 2 is widely used in :

- Flour Milling – Optimizing wheat selection, blending, quality control.

- Bakeries & Food Production – Ensuring dough consistency for bread, pastries, and snack foods.

- R&D Ingredient Testing – Developing new recipes and monitoring enzyme and additive effects.