List of Industries

ADVANCED SOLUTIONS FOR SPECIALTY CHEMICAL & OLEOCHEMISTRY

The oleochemical and specialty chemical industry requires a high level of precision and quality control in its manufacturing processes. Analytical testing is essential for ensuring that raw materials, intermediates, and finished products meet the required specifications for purity, quality, and safety.

At Nexus Analytics, we provide advanced analytical testing services that help oleochemical companies to monitor and maintain the quality and consistency of their products. Our state-of-the-art equipment, combined with our team's expertise in the industry, enables us to perform accurate and reliable analyses that aid in the development of new formulations, optimize production processes, and support the implementation of new manufacturing technologies.

Incoming Raw Material

Material Identification

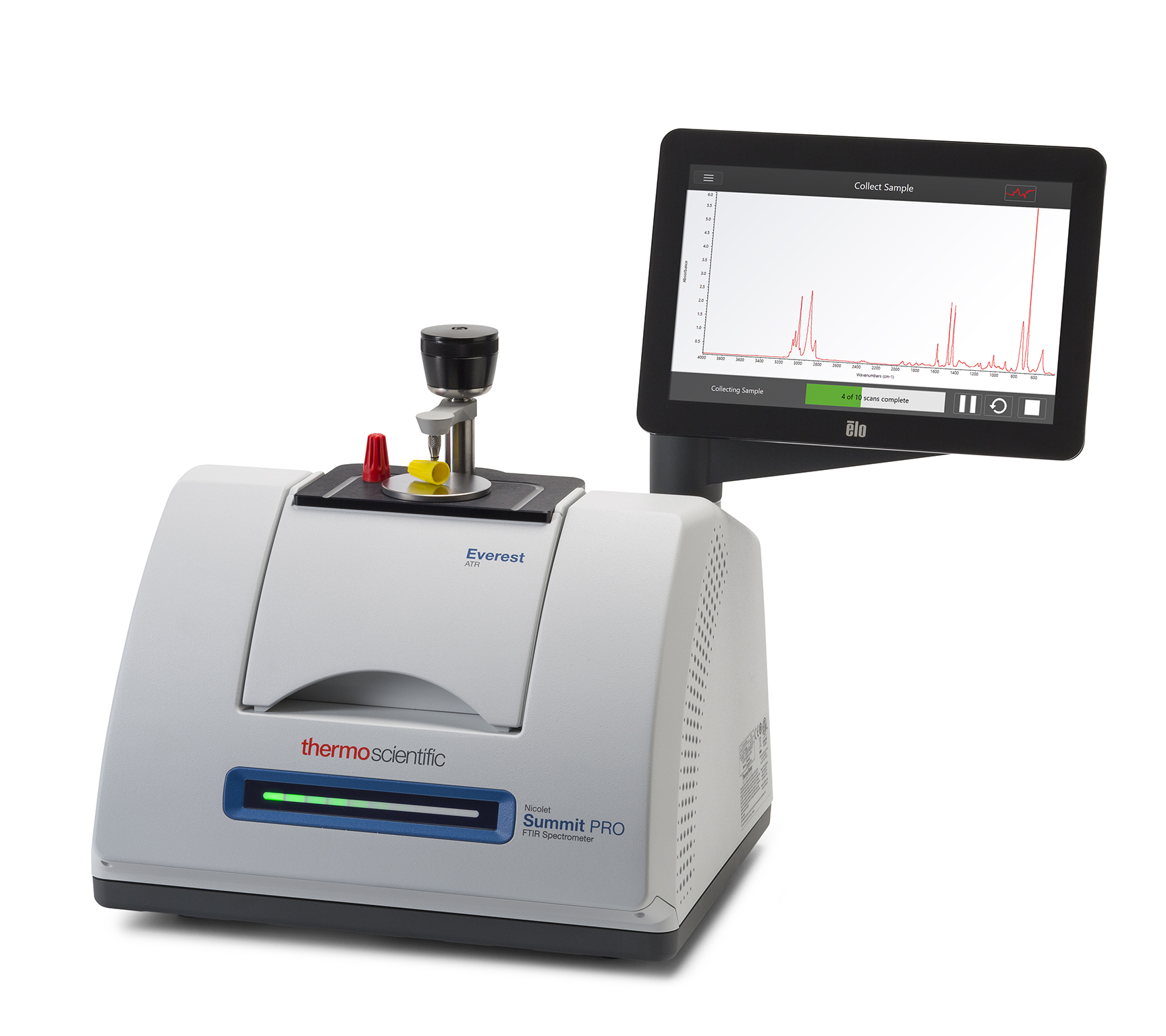

Fourier Transform Infrared Spectrometer (FTIR)

~ Identification and quantification analysis for raw materials

Particle Size Analysis For Material Quality Conformance to Certificate of Analysis (COA)

Particle Size Analyzer

~ Particle size analysis/Particle distribution analysis of incoming raw materials for QA, QC, formulation and R & D purposes

R&D Formulation/ QA&QC

Material Characterization & Rheology

Thermogravimteric Analzyer (TGA)

~ Material thermal decomposition & Thermal stability study, Compositional analysis(moisture, volalite, main component/material , ash content analysis ), thermal degradation analysis

Material Characterization & Rheology

Differential Scanning Calorimter (DSC)

~ Melting point, crystalization point, thermal event enthalpy analysis, specific heat capacity determination, oxidation study( Oxidation Induction Time, Oxidation Onset Temperature ), curing reaction

Material Characterization & Rheology

Rheometer

~ Rheology study, viscosity study , modulus, shear thinning, thixotropy , shear thickening property of materials

Dosing & Reaction Monitoring

Fourier Transform Near-Infrared Spectroscopy (FT-NIR)

~ Quantitative analysis and monitoring for quality control of organic samples

Dosing & Reaction Monitoring

Online FT-NIR

~ Quantitattive analysis and monitoring tool for at-line or in-line quality control of process/production samples

Product Separation (Colloidal Stability)

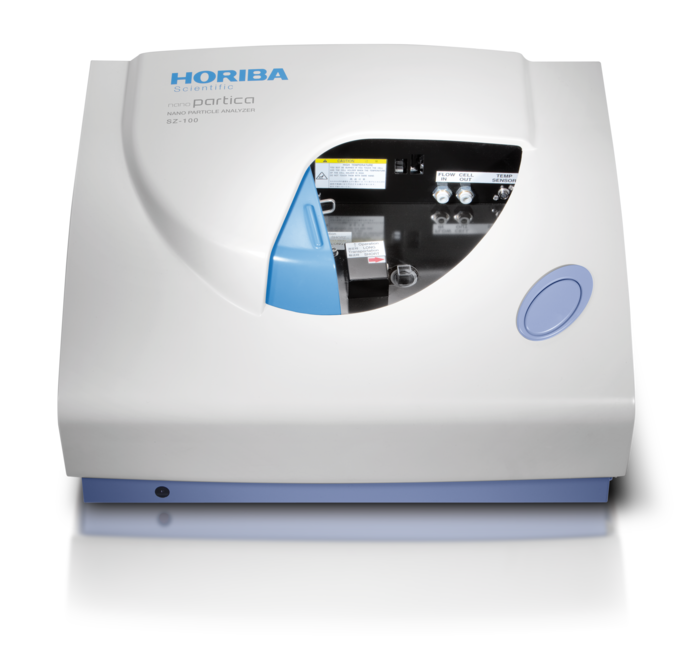

Dynamic Light Scattering

~ Particle size determination of submicron or nano-particles. This technique for size determination is based on light scattering of particles in Brownian motion. Provides zeta potential measurement that indicate the colloidal stability of material

Finished Goods

Final QC

Fourier Transform Near-Infrared Spectroscopy (FT-NIR)

~ Quantitative analysis and monitoring for quality control of organic samples

Final QC

Fourier Transform Infrared Spectrometer (FTIR)

~ Identification and quantitative analysis for materials/ingredients for final QA/QC purposes

Final QC

Particle Size Analyzer (Laser diffraction)

~ Particle size analysis/Particle distribution analysis of finished goods/product for QA/QC purposes

Final QC

Dynamic Light Scattering

~ Size determination of submicron or nano-particles. This technique for size determination is based on light scattering of particles in Brownian motion. Provides zeta potential measurement that indicate the colloidal

Final QC

Surface Analyzer

~ Determination surface tension of liquid, surface free energy of substrate and contact angle analysis

Cleaning Efficiency

Surface Tension/Tensiometer

~ Determination of surface tension of liquid, surface free energy of substrate, Critical Micelle Concentration ( CMC ) study for cleaning surfactant