What is Dynamic Contact Angle (DCA)?

When we talk about “Dynamic Contact Angle” (DCA), there are two quite different subjects that may be addressed:

- Time-Dependent Contact Angle (tDCA)

- Motion-Dependent Contact Angle (mDCA)

What is the Time-Dependent Contact Angle (tDCA)?

The term Time-Dependent Contact Angle (tDCA) refers to the time-dependent behavior of contact angle value when a drop is deposited onto a surface: it changes with time after deposition, in fact with a clear trend.

For an ideal surface, the contact angle should reveal a more or less constant value after deposition, independent of contacting time. Such a surface is assumed to be planar, smooth, impenetrable, and chemically homogeneous, and inert against the test liquid used. If a surface shows a clear trend of time-dependence in contact angle value, it reveals that it is either NOT impenetrable or chemically NOT inert against the test liquid, or neither impenetrable nor inert.

Why is it important to know tDCA?

This time-dependence behavior is an indication that the properties of the surface are changing after contacting with the test liquid, that is, the test liquid is altering the properties of the solid surface, either chemically (e.g. reaction), or physically (e.g.imbibition/spreading), or both of them. That a chemical reaction will change the properties of a surface is self-evident.

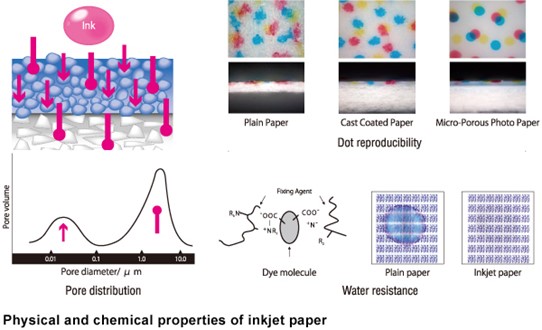

However, the penetration of a test liquid into the solid surface will change its properties as well. Determination of tDCA on those surfaces delivers important information of time-dependence of the wetting process, and a lot of industrial processes are high dynamic, that is time-critical, like printing.

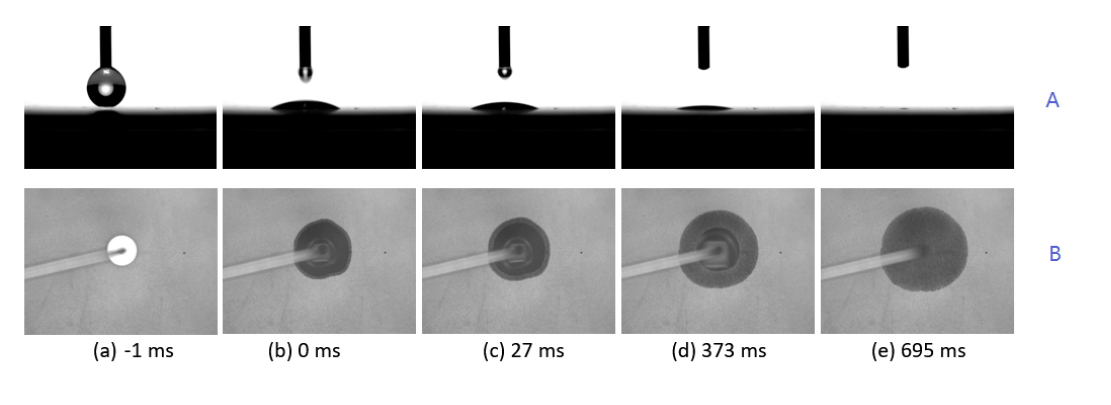

The figure below shows the time dependence of a drop on a porous membrane surface, the images are taken from side (A) and from top (B) simultaneously. It is clearly to see that the liquid imbibes into and spreads over the surface at the same time.

For those kinds of sample surfaces, it makes little sense to report a “mean” value for the contact angle as the measurement result, but rather the complete time-dependence behavior of contact angle (e.g. in form of a curve or table) should be referred.

What is the Motion-Dependent Contact Angle (mDCA)?

Most commonly and frequently, however, the term “dynamic contact angle” is referred to the Motion-Dependent Contact Angle (mDCA) and to the techniques that measure the contact angle during motion.

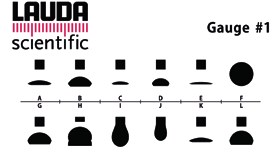

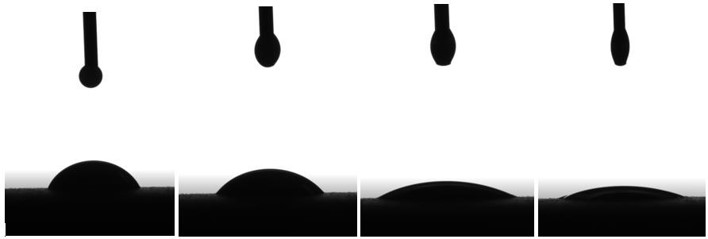

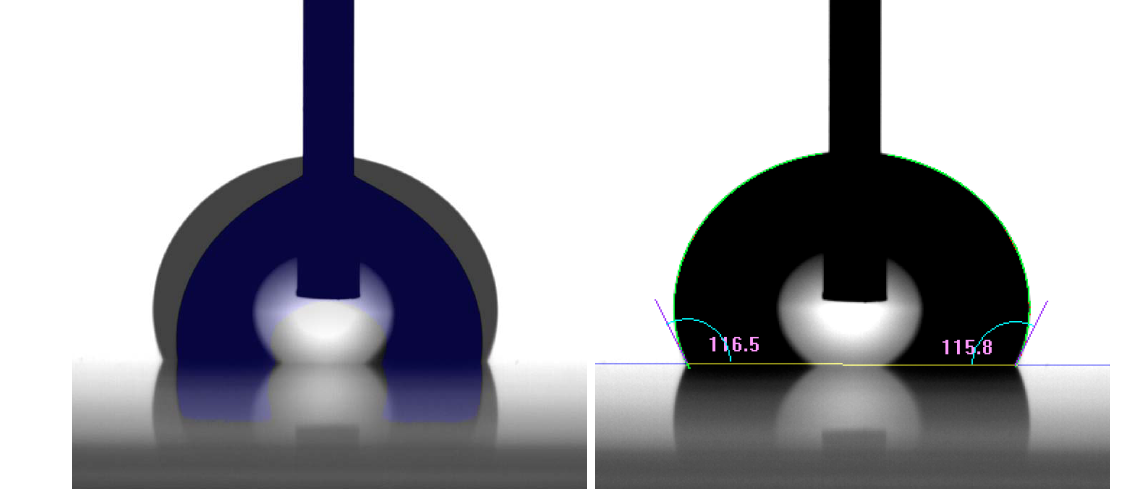

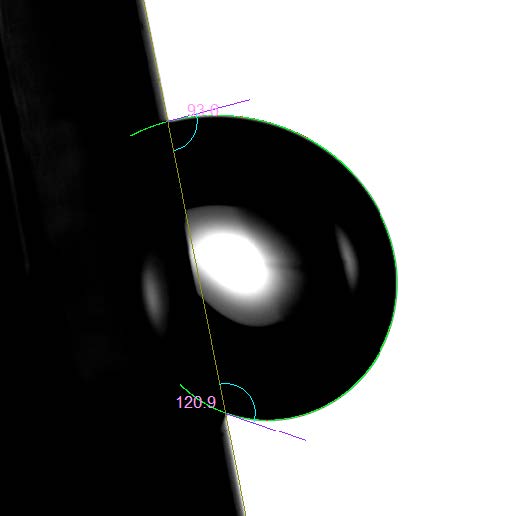

Motion means here the dynamic (movement) of a drop, either in its form/size, or in its three-phase boundary, or combination of all. This is usually accomplished by adding liquid to a static drop on a surface (whereat the dispensing needle remains usually in the drop to avoid unnecessary vibration or distortion of the drop, see pictures on the left) and thus altering its form/size and pushing the wetting front of the liquid across the unwetted surface.

How is Dynamic Contact Angle Measured?

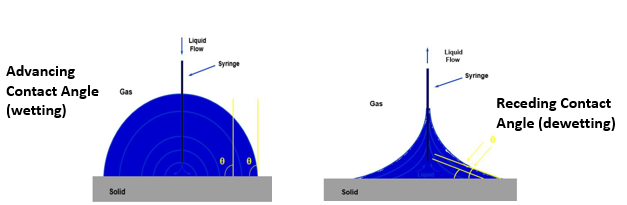

The contact angle measured during drop expansion is referred to as the advancing contact angle. It is a measure of the dry-wetting behavior of a liquid or a surface, i.e., of the fluid mechanics on a freshly wetted surface.

On the other hand, continuously removing liquid from a drop will decrease its size and thus cause dewetting of the surface. The contact angle that is formed during the shrinking of the drop is referred to as receding contact angle r. The receding contact angle is a measure of the remaining interaction forces between the liquid and the solid. The difference between the advancing and receding contact angle is referred to as contact angle hysteresis (CAH).

What is contact angle hysteresis (CAH) and how is it measured?

Contact Angle Hysteresis (CAH) is a means of assessing the mean roughness and/or inhomogeneity of the sample. If the surface is chemically and physically sufficiently homogeneous, advancing and receding contact angles are constant and CAH is quite low.

The mDCA data provides thus exhaustive information on the properties of a surface, whereas the absolute value of static contact angle is often dependent of the pre-history of formation and motion of a drop. It is therefore always preferable to obtain mDCA results over a single static contact angle value.

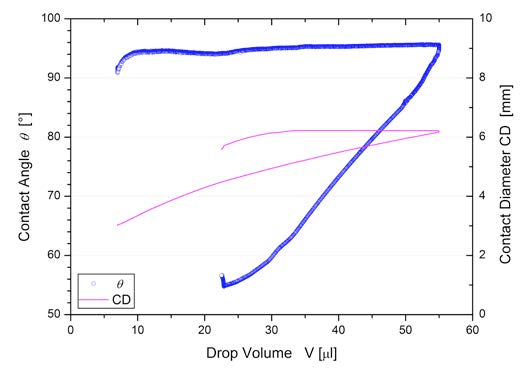

The following picture shows a measurement of mDCA by using the Expanding/Shrinking method mentioned above.

It can be seen that, by adding liquid into the drop, CA (contact angle) increases with increase of CD (drop’s contact diameter) to a maximum at the beginning, and then stays nearly constant with further continual increasing of CD; As the removing of liquid from the drop begins, CA decreases immediately and continually while CD stays nearly constant.

In the later phase, CD begins finally to decrease, which leads to small fluctuations of CA. At the last phase, CA rises steeply again, as CD decreases abruptly. By plotting CA from one side of the drop against its corresponding three-phase contact coordinate, it is clearly recognizable that the fluctuation of CA value is closely related to the motion of the contact line.

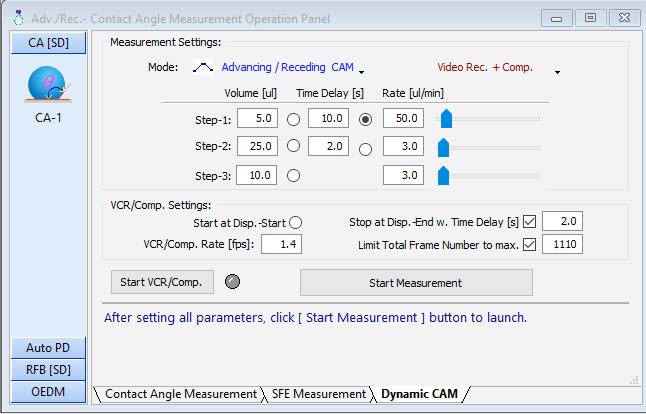

SurfaceMeter software brings with a Measurement Template extra for the measurement of mDCA (s. picture), which makes the measurement easier and straightforward. By choosing the measurement mode “Video Rec. + Comp.”, you can monitor the results of the measuring process in real-time, while every image frame that has been used for computation is stored at the same time into a video frame. The video frame can be opened again later for recomputation (if necessary) or for review.

Furthermore, the software provides two best computation methods for mDCA-measurement, namely the TrueDrop method and the Young-Laplace (ASD) method. These two methods can treat both symmetrical and (highly) asymmetrical drops, and are not affected by the embedding needle within the drop.

Moreover, the unique additional X-axis of the dispensing carrier module in LAUDA SCIENTIFIC Surface Analyzer LSA100 or LAUDA SCIENTIFIC Surface Analyzer LSA 200 series, makes the necessary adjustment during the measuring process so easy that it is truly a pleasure to work with.

Alternative Approach for mDCA measurement – Tilting Stage

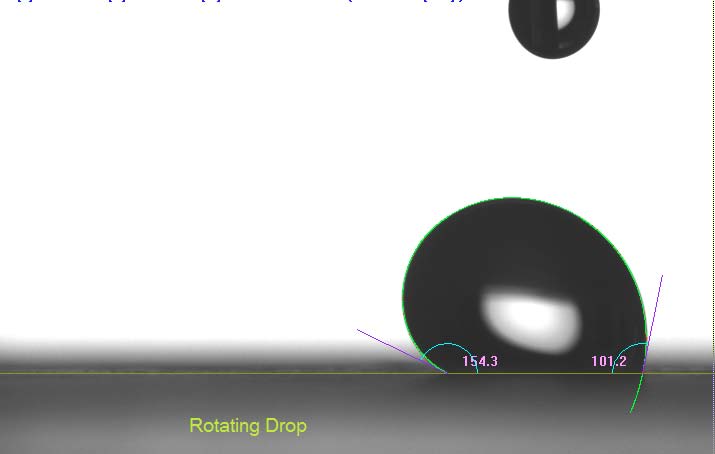

Another common method for measuring mDCA is the Tilting Stage (or Plate) method (ATS 360 extension module). By putting a sample surface on a tilting stage and placing a drop onto the surface and tilting the latter at a controlled speed slowly, the change of contact angles and triple-phase contact line positions at the front and backside is followed (s. pictures below), until the the drop starts to slide (or roll), or the maximum tilting angle (mostly 90 degrees) is reached.

Thus, the dynamic contact angles at the front (“downhill”) and back end (“uphill”) of the drop can be determined, and their variation, as well as the variation of the coordinates of three-phase contact points at both ends, with the tilting angle.

With this information, advancing and receding contact angle can be determined. Again, for computing tilted (highly asymmetrical) drop images, special computation methods like the TrueDrop method and the Young-Laplace (ASD) method are required

Alternative Approach for mDCA measurement – Retention Force Balance (RFB)

Recently LAUDA Scientific introduced a new inimitable technique for determining mDCA and retention force at the same time, this is the so-called Retention Force Balance (RFB) module or the Rotating Drop method. It is based on the centrifugal force to drive a drop on a rotating solid surface to move (motion!) and extends the functionality and applicability of the Tilting Stage method further by overcoming some of its limitations.

Recommended System Setup for Dynamic Contact Angle Measurements (DCA)

Where do we apply Surface Science?

- Printing

- Cleaning

- Pesticides

- Gluing

- Inks

- Coating

- Semiconductors

- Textiles

- Powder Wetting

- Viscous Materials

- Cosmetics & Personal Care Products

- Painting

This article is contributed by Lauda Scientific GmbH.

Since 1967 LAUDA Scientific has been manufacturing precision measuring instruments for determining the viscosity of polymer solutions, optical contact angle measuring instruments for measuring the free surface energy and the wetting behavior, and classical tensiometers for determining the surface and interfacial tension of oils and surfactants.

Nexus Analytics is appointed as an exclusive distributor by Lauda Scientific in Malaysia and Singapore.

Book a free demo with us now!

Please fill up the form below. Our team will contact you as soon as possible. Thank you